Joints à billes de haute précision pour les systèmes de commande automobile et industrielle

[ Description du produit ]

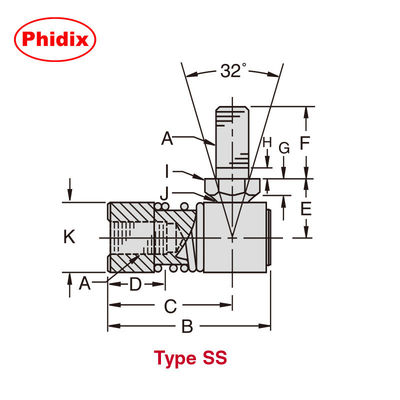

Le joint à bille est un composant mécanique essentiel conçu pour connecter des tiges de commande, des liaisons ou des câbles tout en permettant un mouvement libre dans plusieurs directions.Il fournit un mouvement rotatif et angulaire lisse, assurant un contrôle précis et une souplesse dans les systèmes mécaniques et industriels. Fabriqué en acier au carbone ou en acier inoxydable de haute qualité, le joint à billes offre une résistance supérieure, une résistance à la corrosion,et des performances durablesIl est largement utilisé dans les machines automobiles, marines, agricoles et industrielles pour le contrôle de l'accélérateur, le changement de vitesse, la direction et la transmission de mouvement.

[Applications]

• Systèmes de commande automobile (accélérateur, frein, embrayage, changement de vitesse)

• Automatisation industrielle et robotique

• Connexions moteur et direction

• Machines agricoles et de construction

• équipement aérospatial et de défense

• Ensembles de câbles de commande poussée-tirée

• Systèmes de commande de mouvement et d'actionnement à distance

[Caractéristiques]

• Fournit un mouvement fluide dans plusieurs directions

• Haute précision et réaction minimale

• Construction en métal durable avec revêtement anticorrosion

• Disponible en options de fils mâles et femelles

• Facile à installer et à entretenir

• Compatible avec les systèmes de liaison standard et personnalisés

• Protection contre la poussière et les graisses

[Les avantages]

• Durabilité accrue: conçu avec des matériaux de qualité supérieure pour une longue durée de vie.

• Compatibilité polyvalente: s'adapte à une large gamme de câbles de commande et d'assemblages de liaison.

• Performance stable: maintient un contrôle précis même sous vibration et charge.

• Faible entretien: la conception facultative de l'autolubrifiant réduit au minimum les besoins de maintenance.

• Conception personnalisable: Disponible en plusieurs tailles de fils, matériaux et finitions.

[Questions fréquemment posées]

Q1: Le joint à billes peut-il être personnalisé?

Nous fournissons des tailles, des fils, des matériaux et des revêtements personnalisés selon vos dessins ou vos spécifications techniques.

Q2: Quel matériau est le mieux adapté aux applications extérieures ou marines?

L'acier inoxydable (SS304 ou SS316) est recommandé pour une résistance supérieure à la corrosion.

Q3: Ce joint à billes peut-il être utilisé avec des câbles de commande push-pull?

Oui, il est entièrement compatible avec les ensembles de câbles standard et personnalisés.

Q4: À quelle fréquence doit-on lubrifier l'articulation à billes?

Si vous utilisez un type standard, appliquez la graisse tous les 3 à 6 mois.

Q5: Quelle est la différence entre un roulement à billes et un roulement à bout de tige?

Un roulement de bout de tige comprend généralement une tige filetée pour le montage, tandis qu'un joint à billes est principalement conçu pour des connexions de liaison mécaniques flexibles.

[ Réelle photo ]

Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!  Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!